Overview

As oil and gas resources become harder to find, producers are forced to operate in environments of ever increasing severity and risk. Often operating in High Temperature High Pressure (HTHP) applications, the consequences of a catastrophic failure to personnel, the environment and infrastructure are immense.

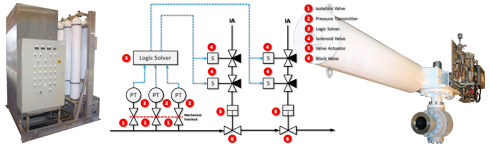

To help manage the increasing and unprecedented risk, the concepts of Safety Instrumented Systems (SIS) and Safety Integrity Levels (SIL) were created and applied. One such SIS type, is the High Integrity Pressure Protection System (HIPPS). A HIPPS is an independently instrumented protective device, and acts as the last line of defence for protecting downstream operations from over pressurization.

Typically certified to SIL 3, a HIPPS gives producers the most dependable pressure protection device available in the market today.

Key Features & Benefits

We understand that operators have far more pressing issues than expediting multiple vendors, and managing the certification process for HIPPS. We provide a single point of contact for the provision of comprehensive turnkey and integrated solutions.

- Full engineering design support for any HIPPS application

- Full compliance with IEC 61508 Edition 2 up to SIL 3; including system and sub-system calculations and documentation set:

- SIL calculations

- Safe failure fractions

- HFT requirements

- Partial Stroke Testing (PST) frequency determination

- 3rd party certification

- Fast closure times up to 2 seconds

- API and ASME valves up to 42”

- Skid design and fabrication

- Installation, commissioning and servicing support

- Valve actuator designs and manufacturing based on 30 years experience in the Oil & Gas industry

- World class and proven logic solver

- Full diagnostics capability

- Compact manifold design control systems

- Hydraulic power units

- All instrumentation